Product

Environment-related Materials

Biomass Plastics Example 2

-

Successfully formed a planters and pots from waste biomass plastic tableware collected from the 2005 EXPO Aichi, Japan.

We played a role in demonstrating the purpose of the EXPO by demonstrating the potential for diverse recycling of BP products introduced at the EXPO. The following are examples of development.

-

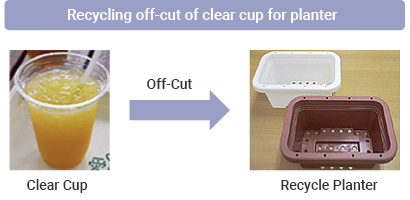

Recycle planter (small)

This is a planter formed from scrap materials of BP-made clear cups used at the venue.

We successfully established a formulation and molding conditions of the biomass planter that we jointly developed. And the Bioindustry Association Bioprocess Commercialization Development Business R&D Consortium provided us the raw materials, such as scrap materials generated during the molding of BP tableware (clear cups) at the EXPO.

The raw material(scrap material of clear cup foaming) is re-pelleted by the R&D Consortium.

Earth friendly Iron oxide pigments (steel billets) are also used for colorants. -

Acknowledgment: R&D Consortium of Bio-Industry Association Bio-process Practical Application Development Projects

BP is said to be a difficult-to-form material because of its low elongated stickiness (stickiness at the time of melting). In the case of BP, which can be molded without problems with existing resins, there were technical issues to be overcome, such as the difficulty of uniformly flowing and the difficulty of separating molds. In the past, the recycling of BP was regarded as "bio-recycling" (composting and methane gasification), because damaged goods used as tableware could deteriorate the material itself.

BP is said to be a difficult-to-form material because of its low elongated stickiness (stickiness at the time of melting). In the case of BP, which can be molded without problems with existing resins, there were technical issues to be overcome, such as the difficulty of uniformly flowing and the difficulty of separating molds. In the past, the recycling of BP was regarded as "bio-recycling" (composting and methane gasification), because damaged goods used as tableware could deteriorate the material itself.

We consider the recycling of BP dishholdings, which were introduced at the EXPO into utility materials (part) using scrap materials and damaged products as raw materials, to be the first case to demonstrate the material recyclability of BP. In the case of BP, there were many issues in material recycling realized in existing resins. However, we will participate in demonstration trials and overcome these issues to express our respect to the companies that have succeeded brilliantly.

In order to demonstrate BP's material recyclability, we are also thankful to the 2005 International Exposition Association of Japan and all of our exhibitors, who have provided support for its realization and exhibition at the Aichi EXPO.

※ Excerpt from the website of the Bioindustry Association

Size: 310 mm (Width) ×220mm (Depth) ×150mm (Height)

Developed by: Showa Kosan Co., Ltd.