Product

Environment-related

Biomass Plastics Example 1

-

Technological Trends Related to Material Recycling of Biomass Plastics

Material recycling of biomass plastics has rarely been examined so far, partly because of the small volume of its distribution in the market. At the 2005 EXPO Aichi, Japan where biomass plastics were used in large quantities, it can be said that one of the few demonstration tests of material recycling were conducted.

Material recycling of biomass plastics has rarely been examined so far, partly because of the small volume of its distribution in the market. At the 2005 EXPO Aichi, Japan where biomass plastics were used in large quantities, it can be said that one of the few demonstration tests of material recycling were conducted.

Tokai Kasei Co., Ltd. and us are conducting demonstration tests related to material recycling of PLA (biodegradable polymers), such as the production of planters used in the JAPAN GAMES(National Sports Festival) at Okayama prefecture in autumn 2005, using the odd stock of tableware and other materials used at the Aichi EXPO. -

Forming "Planters" Using Recycled Materials

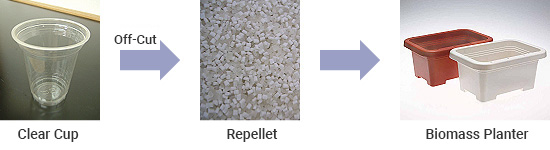

To respond the request from the Bio-Industry Association and the R&D Consortium for the Development of Bio-Process Practical Application, we tried forming the Planter using recycled materials that were repalleted with fractional materials generated during forming, etc., of the clear cups used at the Aichi EXPO.

-

The key points in prototype production are as follows.

- Introduced 20% recycled materials into polylactic acid raw materials and molded them by injection.

- The planter could not be released due to the resin flow was slow and it entered into embossed surface of the mold. Therefore, we reduced embossed surface of the mold.

- However, burrs were spatted and the release was not good, we change to the larger molding machine.

- There is a risk of longer heating time in case of molding is temporarily halted, the heating temperature may reach the decomposed temperature, therefore we cautiously not to slow down the raw material input.

- Since the specific gravity wloud be large and the weight wloud become heavy, we have considered reducing the amount of tarc smelted into polyurethane and reducing the weight. (PP: Approx. 0.95 This time: Approx. 1.41)

-

Forming Seedling Pots from off-cut materials of Clear Cup production

We tried forming the Seedling Pot using the collected used Clear Cup at Aichi EXPO.

-

The key points in prototype production are as follows.

- Clear cups were crushed.

- The raw materials used in ordinary biodegradable seedling pots were mixed with crushed raw materials and molded by blow molding.

- There was no problem with molding for 10% of crushed raw materials, but if 20% to 30% were introduced, the probability of thickness deviation or poorly molded became higher.

- Higher percentage of crushed clear cup materials, more the defect molded product, it is due to differece between the seedling pot resin(blow modling) and clear cup resin(not blow molding).

- We think that it is reasonable to have a blending ratio of up to 10%.

-

Demonstration of the reuse of bio-recycling planters

We considered further recycling and molding of bio-recycling planters used in the JAPAN GAME(National Sports Festival) at Okayama prefecture. We mixed only same materials and thus there is no risk of defect molding.

However, it is likely that fine dirt and impurities will adhere to the product even if it is washed and it should be examined that how the degree of adhesion of impurities will affect the product. In addition, since it was in contact with soil or water (moisture), it is considered that decomposition has begun. Therefore, it is necessary to examine the duration and durability and moreover you will probably need enough drying after grinding the planter.

※ Documents provided to the Japan Organic Resources Association.